Sheet Metal Stamping process. We are recognized in Germany and abroad especially for our expertise in thermoforming progressive tools.

Pdf Design Of Progressive Draw Tool Semantic Scholar

Received 2D drawing Progressive DIE Design from client in AUTOCAD files request to make 3D Modelling for Design Review fabrication purpose CAM Process liked this model Published 4 years ago in Manufacturing Services.

. In this work a real time design of a simple piercing press tool and manufacturing of a prototype is made along with static analysis of punch where the output is a Pierce hole and notch hole. Starting a Progressive Die Design. Accurate tool making 4.

The work piece on progressive dies travels from one station to another with separate operations being performed. Attempt is made on to learn the press tool design materials manufacturing used for press tool and calculations involved in it. A typical progressive die design may start off like this.

Here is a five-step formula for a successful progressive tool and die design. Located in Lloydminster Alberta we utilize the latest in 3D modeling and engineering software coupled with advanced CNC machinery to take your idea from start to finish - all the way. By Yalçın CAN Part mode.

Shown in fig is a rather deep shell that has been drawn from a flat sheet. Progressive tool and blank with draw press tool. SOLIDWORKS Rendering June 10th 2021 Metal Hinge part mold ani.

DESIGN OF PROGRESSIVE DIE progressive die performs a series of fundamental sheet metal operations at two or more stations during each press stroke in order to develop a work piece as the strip stock moves through the die. PROGRESSIVE TOOL Progressive tool performs two or. Progressive tool Progressive tool differs from the stage tool by the.

Forming dies are typically made by tool and die makers and put into production after mounting into a press. Autocad manufacturing-design catia-v5 3d-cad-design progressive-die-design. Design And Manufacturing Of Progressive Press Tool 22 Width 14mm Area 22855mm2 E 22855 x 100 x 2 27x28 6046 Conclusion.

Knowledgeable press setting According to upper factors this paper is aimed at the optimum die design through the FE analysis Pro-E. Excellent tool design 3. BIBLIOGRAPHY 1 Press tool technology by NTTF technical training centre 2 Tool Design by Donaldson.

Determine the orientation of the part. Press Tool Design Basics. It is efficient to go for a wide run with two rows.

Is a CNC machine shop focusing on the engineering design and manufacturing of downhole tools utilized in the oil and gas industry. The die is a metal block that is used for forming materials like sheet metal and plastic. The press tool commonly known as die dies is an assembly of die punch punch plate punch backplate stripper plate etc.

To produce sheet metal components stamped parts from the flat metal sheet. A customer sends a part print for a stamped part. Progressive Tool Design Inc.

Rotating the part for optimization of the. One of the challenges in progressive tool and die design is the need to rotate the part in the strip. Drawing tools transform flat sheets of metal into cups shells or other drawn shapes by subjecting the material to severe plastic deformation.

Progressive tool and die design are first determined by how the part will be run through the tool and die. PROGRESSIVE DIE DESIGN 5. We have special expertise in the field of progressive tools.

Dies also can contain cutting and forming sections made from carbide or various other hard wear-resistant materials. This type of Press tools are used to perform only one particular operation. For More information on press tools.

Furthermore the aim of least defects could be obtained mostly by revision through the tryout. KeyCreator STEP IGES Rendering March 2nd 2019 progressive stamping tool. The die designer creates a flat blank from the part drawing or CAD model and begins to orientate the blank to optimize material use while.

A Progressive stamping die is a special one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. In many cases a 3D CAD model accompanies the drawing. Our production spectrum ranges from the millimetres-long precision sleeve to the deep-drawn component which is several centimetres long and up to 5 mm thick for the structural and.

The dies cutting and forming sections typically are made from special types of hardenable steel called tool steel.

Progressive Tool Design In Gurgaon Sector 14 By Ab Cad Consultancy Private Limited Id 15654971391

Write About The Construction And Working Of Progressive Die And Combination Die With The Help Of Neat Sketches

Design And Development Of Progressive Tool For Manufacturing Washer Vit University

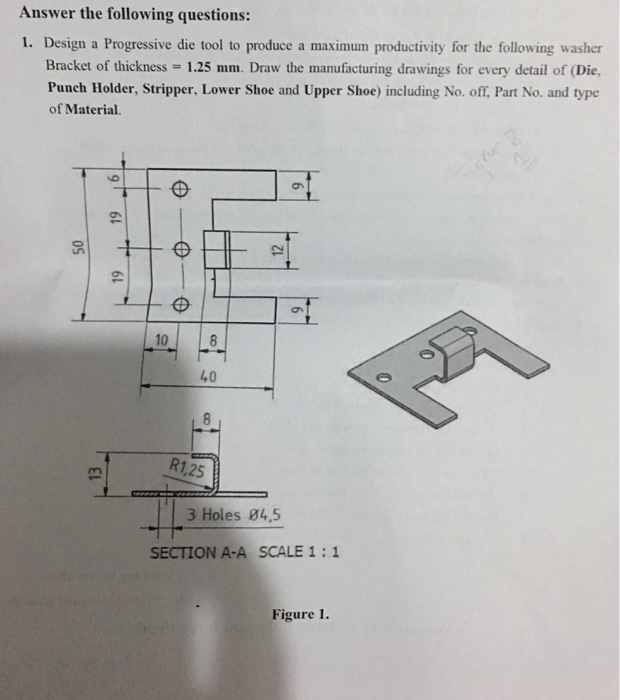

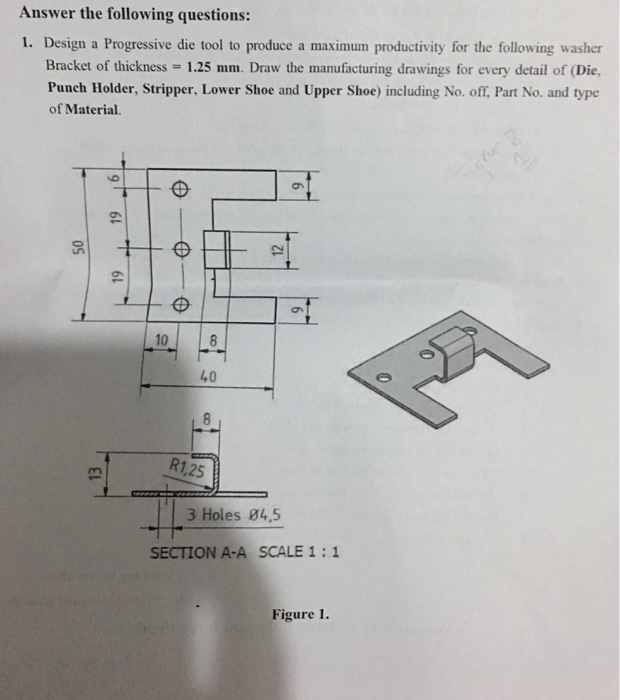

Solved Answer The Following Questions 1 Design A Chegg Com

3d Modelling Progressive Die Design Complete Set Download Free 3d Model By Faizal Mokhtar Cad Crowd

0 comments

Post a Comment